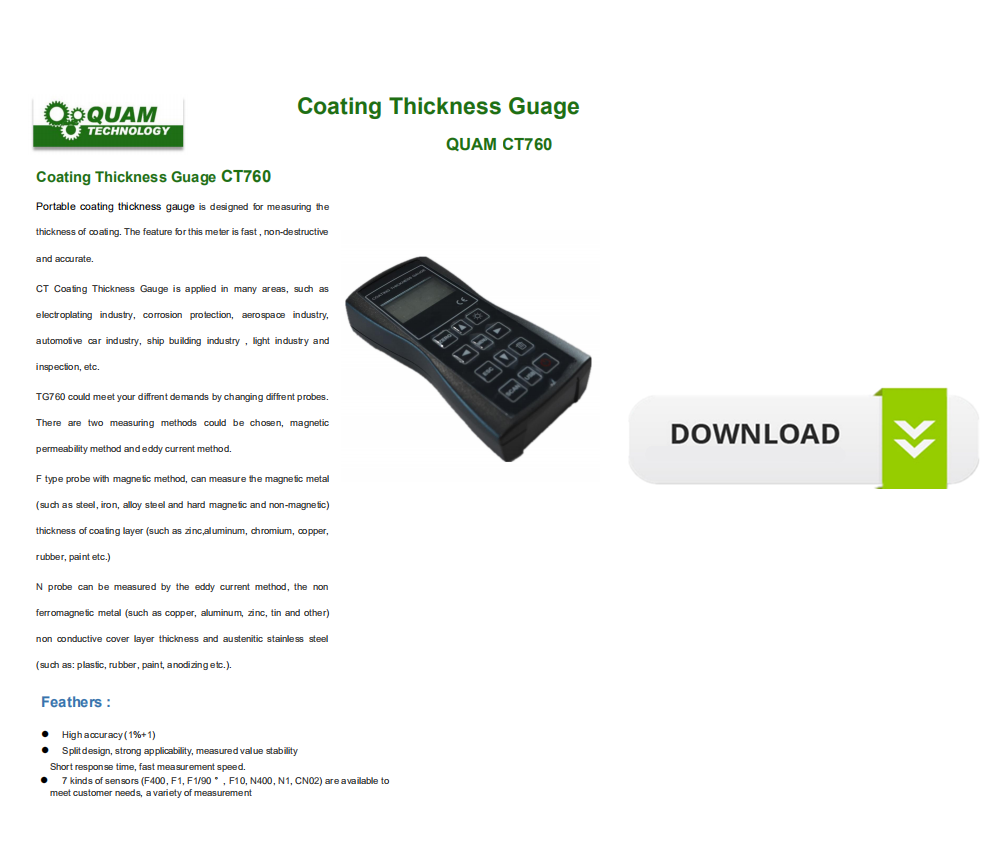

Coating Thickness Gauge CT760

CT760 is designed for measuring the thickness of coating. The feature for this meter is fast , non-destructive and accurate.

CT760 Coating Thickness Gauge is applied in many areas, such as electroplating industry, corrosion protection, aerospace industry, automotive car industry, ship building industry , light industry and inspection, etc.

CT760 could meet your diffrent demands by changing diffrent probes. There are two measuring methods could be chosen, magnetic permeability method and eddy current method.

F type probe with magnetic method, can measure the magnetic metal (such as steel, iron, alloy steel and hard magnetic and non-magnetic) thickness of coating layer (such as zinc,aluminum, chromium, copper, rubber, paint etc.)

N probe can be measured by the eddy current method, the non ferromagnetic metal (such as copper, aluminum, zinc, tin and other) non conductive cover layer thickness and austenitic stainless steel (such as: plastic, rubber, paint, anodizing etc.).

Split design, strong applicability, measured value stability

CT760 is designed for measuring the thickness of coating. The feature for this meter is fast , non-destructive and accurate.

CT760 Coating Thickness Gauge is applied in many areas, such as electroplating industry, corrosion protection, aerospace industry, automotive car industry, ship building industry , light industry and inspection, etc.

CT760 could meet your diffrent demands by changing diffrent probes. There are two measuring methods could be chosen, magnetic permeability method and eddy current method.

F type probe with magnetic method, can measure the magnetic metal (such as steel, iron, alloy steel and hard magnetic and non-magnetic) thickness of coating layer (such as zinc,aluminum, chromium, copper, rubber, paint etc.)

N probe can be measured by the eddy current method, the non ferromagnetic metal (such as copper, aluminum, zinc, tin and other) non conductive cover layer thickness and austenitic stainless steel (such as: plastic, rubber, paint, anodizing etc.).

Split design, strong applicability, measured value stability

Measuring Range

F400:0~400μm N400:0~400μm

F1:0~1250μm F1/90:0~1250μm

N1:0~1250μm F10:0~10000μm

CN02:10~200μm

Accuracy

F400、N400 Probe

One point calibration: (2%+0.7)

Two point calibration:±(1%+0.7)

F1、F1/90、N1、CN02 Probe

One point calibration:±(2%+1)

Two point calibration:±(1%+1)

F10 Probe

One point calibration :±(2%+10)

Two point calibration: ± (1%+10)

Feathers :

High accuracy (1%+1)

Split design, strong applicability, measured value stability

Short response time, fast measurement speed.

7 kinds of sensors (F400, F1, F1/90 °, F10, N400, N1, CN02) are available to meet customer needs, a variety of measurement

- DR

- Electric Spark Leak Detector

- Hardness Tester Series

- Magnetic Flaw Detector

- Surface Roughness Tester Series

- Thickness Gauge Series

- Ultrasonic Flaw Detector

- Electromagnetic ultrasonic thickness

- Spheroidization Rate Meter

- Black Light Lamp

- X-RAY & Electric Energy Material Machine

- Cutting Machine & Polishing Machine

Feel Free To Contact Us: